Hyperlocal Container Farms For Remote Communities

Forget Importing, Grow Fresh Produce Onsite

Farm Year-Round

Grow fresh produce in all climates, year-round.

Beat the Supply Chain

Get your produce on time, every time.

Reduce Food Waste

Harvest only what your community need.

Move & Scale

Move and expand farms based on your needs.

Be ahead of the curve and grow your own fresh produce

Benefits of Container Farms For Remote Communities

By integrating container farms, remote communities not only contribute to environmental sustainability but also enhance their appeal to community members, offering fresh produce and unique experiences while reducing operational costs.

95%

Reduction In Import Cost

40%

Reduction In Food Waste

30%

Reduction In Produce Cost

100%

Reduction In Transport Cost

FAQ

Considering refinancing, but not sure where to start?

Consult with us

Unlock Benefits, Sign Up Today!

Unlock Benefits, Sign Up Today!

New to Container Farming?

Here's a list of frequently asked questions from customers.

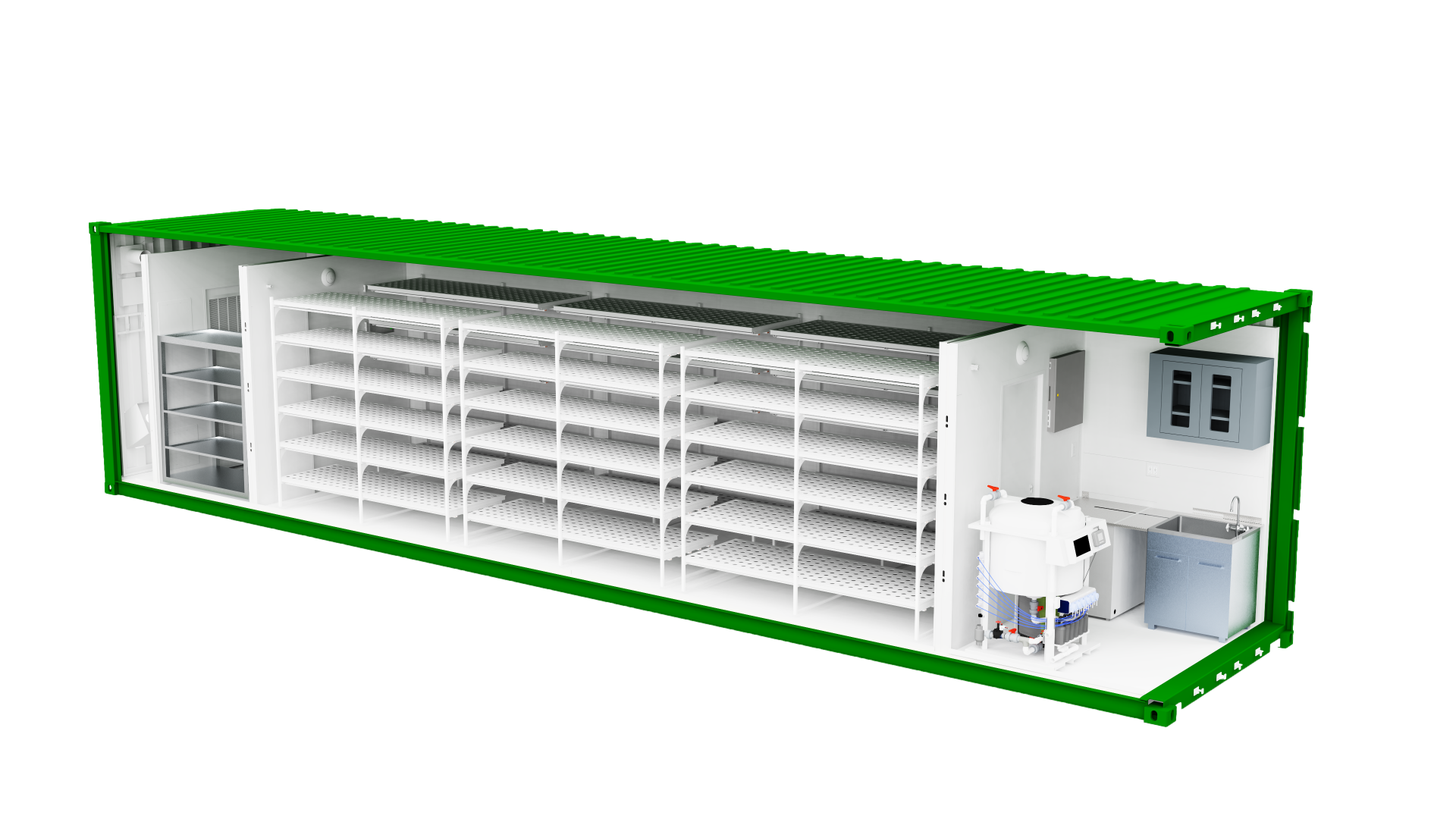

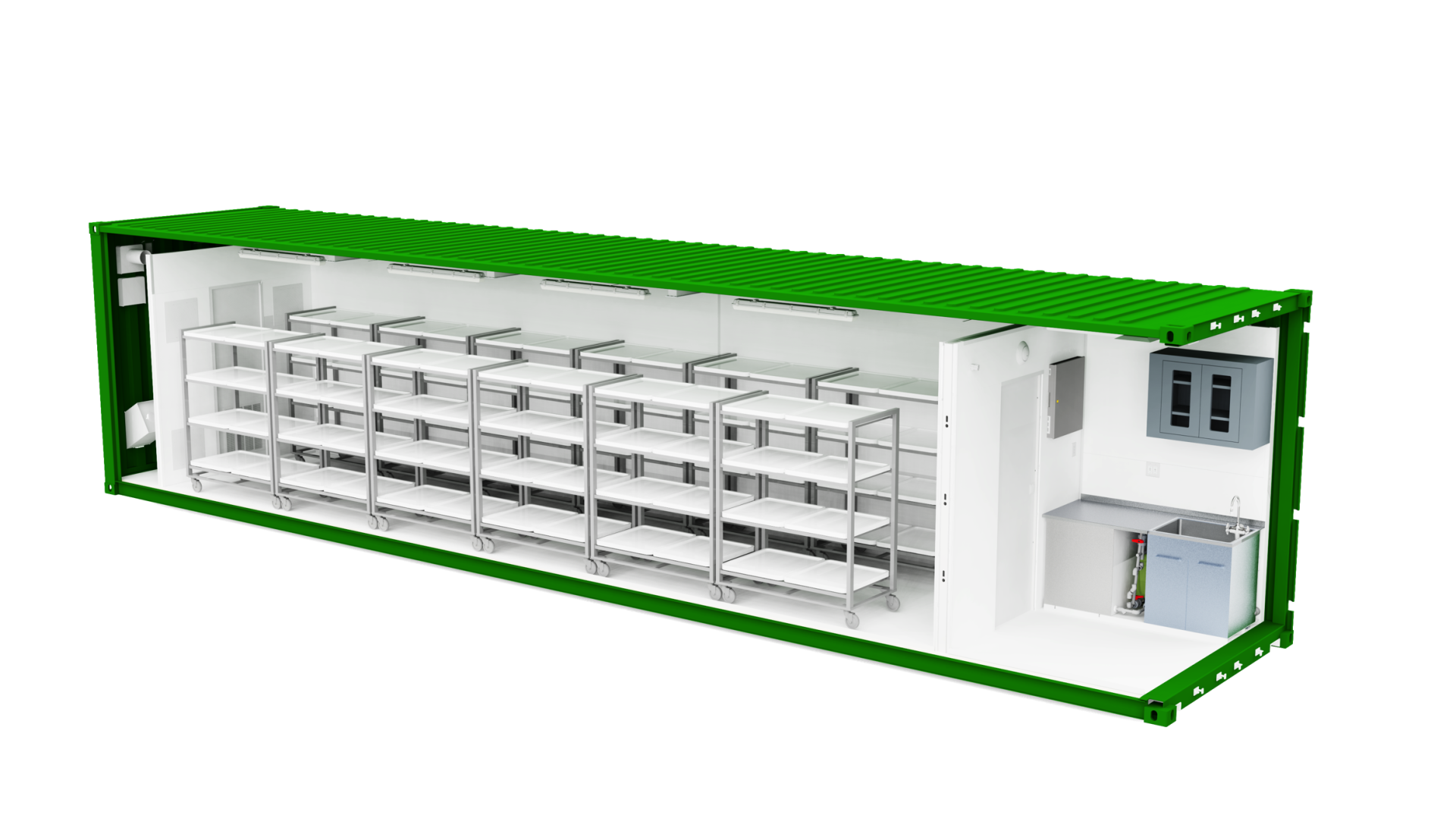

Container farming, also known as vertical farming or indoor farming, is a method of growing crops in a controlled environment within shipping containers. These containers are often equipped with hydroponic or aeroponic systems, LED lights for photosynthesis, and climate control systems. The goal is to maximize the amount of crops that can be produced in a small space, regardless of external weather conditions.

Read about how container farms are bringing the farm-to-table experience to hotels and resorts here.

Container farming offers several benefits over traditional farming. It allows for year-round crop production, independent of weather and season. It uses significantly less water and land compared to traditional farming, making it a more sustainable option. The controlled environment reduces the need for pesticides and herbicides, leading to cleaner, healthier produce. It also allows for farming in urban areas, reducing the distance food needs to travel to reach consumers, which can help reduce carbon emissions.

A wide variety of crops can be grown in a container farm, including leafy greens like lettuce, spinach, and kale, herbs like basil and mint, and other crops like strawberries and fodder. The specific crops that can be grown may depend on the specific setup of the container farm and the technology used.

See more crops here.

The cost of setting up a container farm can vary widely depending on the size of the farm, the technology used, and other factors. The cost could range from tens of thousands to hundreds of thousands of dollars. Ongoing costs include electricity, water, nutrients for the plants, and maintenance of the systems.

The climate in a container farm is controlled using a combination of heating, cooling, and ventilation systems, as well as LED lights that can be adjusted to provide the optimal light spectrum for plant growth. This allows for precise control over the temperature, humidity, and light levels, which can be adjusted to create the ideal conditions for each type of crop. This level of control can lead to faster growth rates and higher yields compared to traditional farming.

Container farming can be more sustainable than traditional farming in several ways. It uses less water, as the hydroponic or aeroponic systems recycle water, and it requires less land, as crops are grown vertically. It also reduces the need for pesticides and herbicides, which can have harmful environmental impacts. However, it does require electricity, which can contribute to carbon emissions if it's not sourced from renewable sources. Additionally, the production and disposal of the materials used in container farms, such as the containers themselves and the LED lights, can also have environmental impacts.

Learn more about sustainable practice here.

Considering refinancing, but not sure where to start?

Consult with us

Browse Our Container Farms

How We Work

01 01

Manufacturing capability

Located in Delta, British Columbia, FarmAnywhere’s 20,000 sq. ft. manufacturing facility is equipped with state-of-the-art tooling. Including; plasma-cutting, welding, 3D printing, spray-painting booth, and skilled trades to complete all electrical wiring, plumbing, fabrication and painting in-house. Our greatest skills are our dedicated employees and expertise of the team.

02 02

Lead-time

Maintaining short lead-times has been a priority for FarmAnywhere. We accomplish this by using ERP (Enterprise Resourcing Planning) tools and collaborating with our suppliers, clients and teams.We pride ourselves in Lean manufacturing principles and overall lead-times average 4-6 weeks after receipt of order (ARO). Some of our standard build configurations are in-stock to deliver sooner

03 03

Design & Configuration

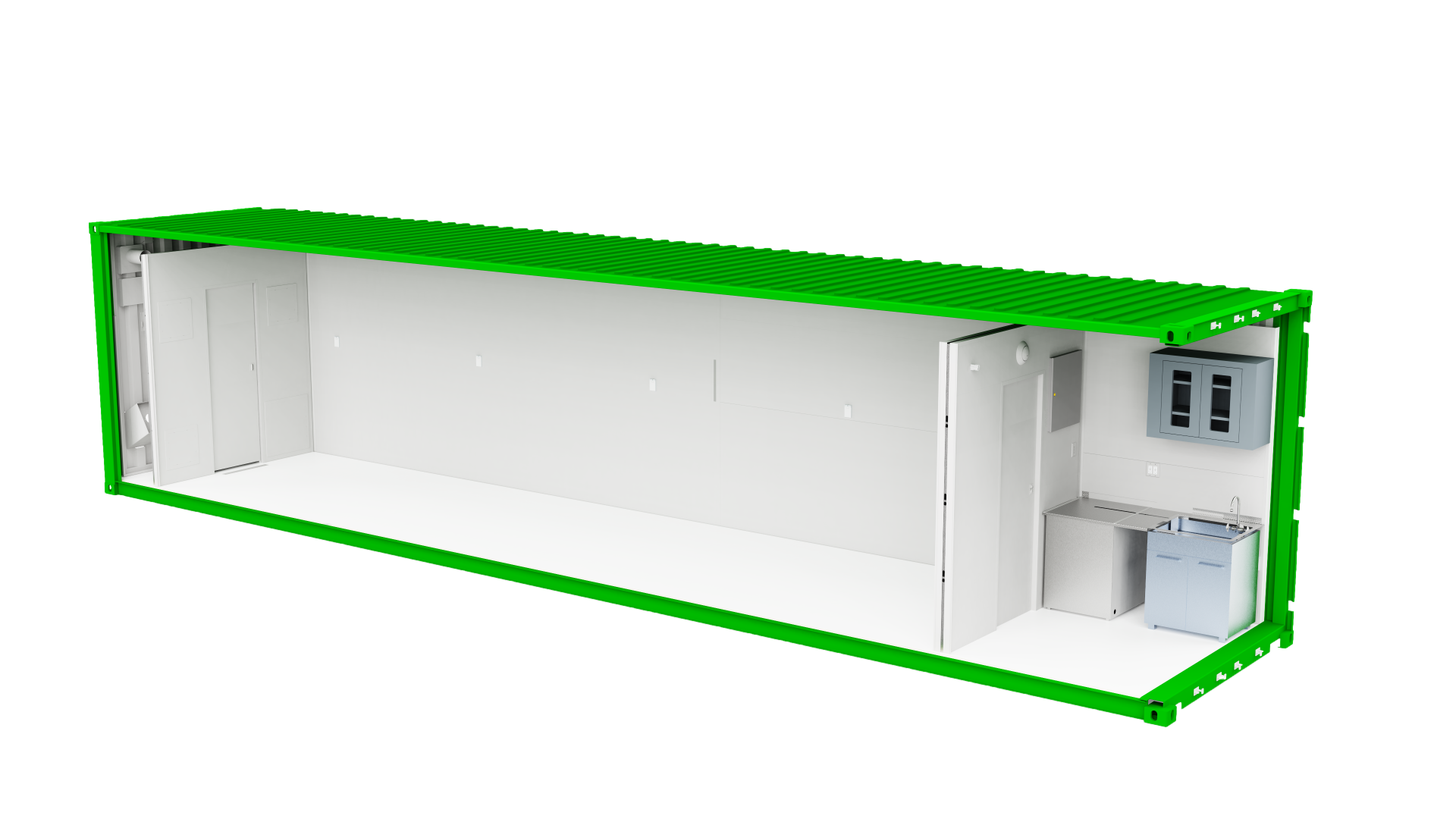

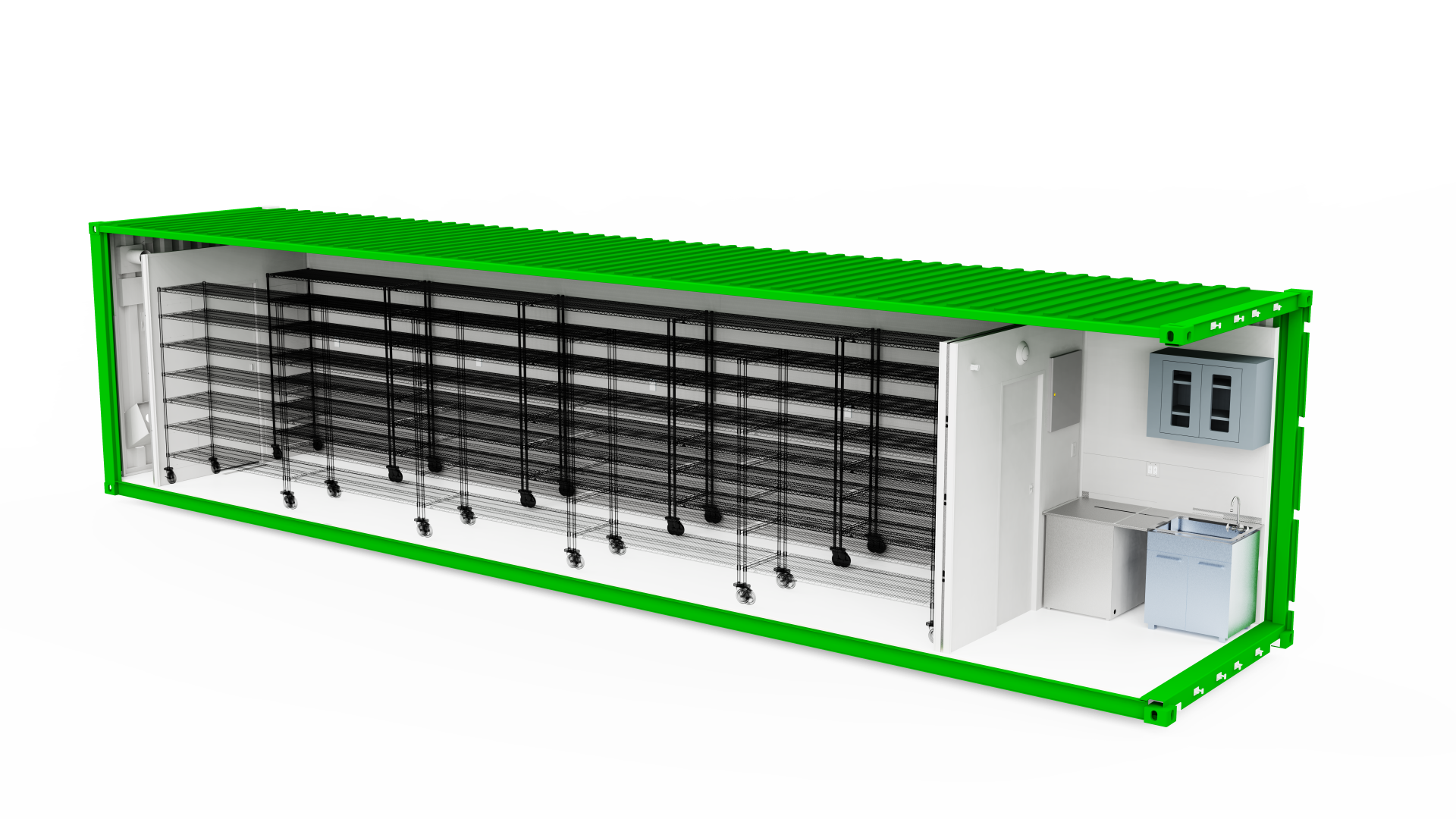

All of our designs are derived from the Lite Shell concept. This basic configuration provides a climate-controlled system complete with all electrical, plumbing and HVAC. From there we outfit the container with unique components specific to your cultivar; leafy greens, mushrooms, hemp, fodder, or microgreens. The feedback we’ve received from farmers is that they want to service and maintain their own equipment. That’s why we use commercial off-the-shelf components where possible. This in turn provides our customers with the benefit of proven design and continued support, without limitations our competitor’s proprietary systems may impose.

Learn More

Browse through our product brochure

Determine the solution that best meets your needs, or reach out to us for assistance.

The Details

Our Process.

A Virtual Tour

Our virtual tour provides an in-depth look at the features and benefits of our container farms, and provides you with a clear understanding of how our equipment can help you to achieve your farming goals.

Don't wait, book your virtual tour today and discover how FarmAnywhere provides you the equipment and technology to grow more, faster, and smarter.

The process

Book A Call

Experience our white glove service.

We encourage you to contact us as soon as possible to discuss how we can help you become a farmer or to expand your current farming capacity.

The Contact

Prepare To Farm

Follow our build process.

Get ready to to receive your farm while we build and ship your solutions.

The Preperation

Looking for more?

Vancouver, BC

Email us today for more info